您搜索的关键词为:

您搜索的关键词为:

13914769779

13914769779KRD45系列高频直缝焊管机组简介及报价

KRD Series High Frequency Tube Mill Line

一、 机型: KRD45整体 Model #: KRD45

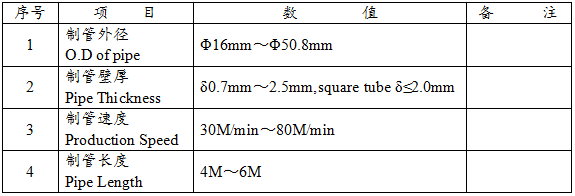

二、 生产能力:

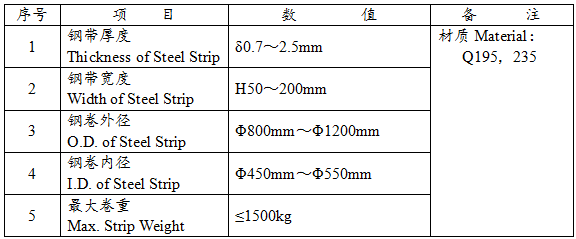

一、 带钢规格:

一、 生产线工艺流程:

原料(带钢卷)→开卷→剪切、对焊→储料→被动矫平→成型轧制→高频焊接→去除外毛刺→喷淋冷却→定径、整型→粗矫直→定尺切断→收管、捆扎。

Raw material (with steel strip coil) → decoiler → shear and butt-welder → strip sccumulator → passively leveling → forming machine → high frequency welding → removing the burrs outside → spraying & cooling → setting machine → straightening → fixed length cutting → run out table → finished tube

二、 机组各单元设备配置简介:

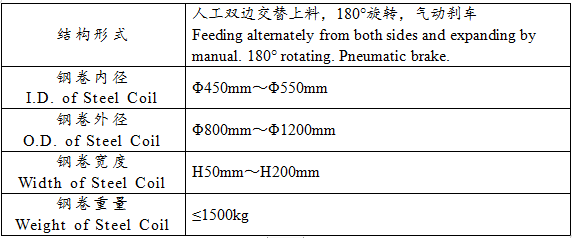

1. 开卷机Uncoiler:

本部套的功能是将整卷带钢拆开,为成型机提供所需原料。

1. 剪切对焊机(用户自配)Shear and Butt-welder (Customer Provided):

本部套的功能是通过人工给料将两卷钢带的首尾不规则部份用机械切除,然后首尾对齐焊接并打磨整平,供应储料箱。

2. 储料箱Sccumulator:

本部套有笼式料箱和卧式活套两种,供用户根据实际情况进行选择。

Including cage sccumulator and horizontal sccumulator. Customer can decide which one to choose based on their conditions.

笼式料箱的作用是在钢带上料并进行首尾焊接的过程中,储存一定量的钢带供应主机轧制,以保证连续生产不停机。

Function of cage sccumulator is to ensure the continuous production during the process of feeding steel strip and welding end to end by storing enough steel strip to supply main rolling.

打料电机Knockout Motor:Y132M2-6-B3 5.5KW 960r/min

卧式活套工作原理是进料装置气缸压紧钢带进料电机驱动送料辊靠磨擦力向储料盘充料,主电机驱动大盘料仓外笼输送辊转动,将带钢以内、外侧相反的方向卷存于内、外侧存料区。一卷钢带存完即停机,等待剪切(头)、对焊完毕,再向料仓充料。

Operating principle of horizontal sccumulator: 1) air cylinder of feeding device pressing the steel strip. 2) feeding motor driving the feeding roller to feed the steel strip into sccumulator by force of friction. 3) Main motor driving the transfer roller rotating to store the steel strip in sccumulator. 4) sccumulator stops when one steel coil finished, waiting for the next steel coil.

活套直径Sccumulator Diameter:Φ3500㎜

打料电机Knockout Motor:YCT200-4B 7.5KW

储料电机Storing Motor:YCT225-4B 15KW

资料暂未上传

资料暂未上传

资料暂未上传